Tool Steel Market Share, Size, Trends, Industry Analysis Report By Material (Chromium, Tungsten, Molybdenum, Vanadium); By Product (High Speed, Cold Work, Hot Work, Plastic Mold, Others); By Process (Rolled, Forged); By Application (Automotive, Shipbuilding, Aerospace, Manufacturing); By Regions, Segment Forecast, 2020 - 2026

- Published Date:Feb-2020

- Pages: 101

- Format: PDF

- Report ID: PM1602

- Base Year: 2019

- Historical Data: 2015-2018

Report Summary

Global Tool Steel market was valued at $4,423.5 Million in 2019 and is likely to grow at an anticipated CAGR of 6.6% over the forecast period. Tool steels can be defined as a distinct family of carbon as well as alloy steels and having features such as better hardness, wear resistance, toughness among others. They are manufactured using different carbide forming materials including molybdenum, tungsten, vanadium, chromium, among others. In some cases, materials such as cobalt or nickel are also used for manufacturing. Different manufacturing processes are used to manufacture the final product depending on the end uses.

Tools are available in a variety of formats, shapes and sizes. They are available in flat, square or round among others. Some of the benefits of tool steel are high micro-purity, minimum presence of trace elements, low segregation, good tolerance limit, ability to comply with etch-graining and polishing. Such advantages have broadened the overall application of tool steels thus favoring market growth.

Know more about this report: request for sample pages

Know more about this report: request for sample pages

Tool steel manufacturing companies work in close contact with their clients to cater to the customized requirements which suit their production processes. For example, to reduce the progressive damage to the tool caused due to reasons such as cyclic mechanical loading, companies provide assistance in selection of the best and optimal tool steel that will guarantee better performance in the overall manufacturing process of their clients and the failure mechanisms associated with it. Companies nowadays provide a wide product portfolio having varying steel grade tools that will cope with different failure mechanisms such as adhesive wear, abrasive wear, breakage and chipping. Thus, this trend ensures that the failure mechanisms can be minimized thus resulting in greater productivity.

Tool steels, when used in plastic molding applications offer excellent machinability, polish ability, homogeneity, low Sulphur content and a good photo etching ability. They also exhibit better toughness and weldability than other counterparts. They also have a high material removal rate thus making them ideal for usage in high cavity designs.

The market is primarily segmented on the basis of Material, By Product, By Process, By Application and geographic region.

Know more about this report: request for sample pages

Know more about this report: request for sample pages

Tool Steel Market Report Scope

|

By Material |

By Product |

By Process |

By Application |

By Region |

|

|

|

|

|

Know more about this report: request for sample pages

Material Outlook

Based on material, the market has been segmented into Chromium, Tungsten, Molybdenum, Vanadium and Others. Tungsten segment is expected to witness the highest growth rate over the forecast period. Tungsten type are generally classified as high speed tool steels and the hardness of the same can be maintained at a temperature up to 540 degree Celsius. Some of the inherent advantages of tungsten type include suitability for high speed machines, resistant to grain growth, high toughness and red hardness, as well as high temperature strength. Such properties render tungsten the ideal choice for usage in hot forming tools and applications as well as high speed machines.

Tungsten tools are also used to make high temperature structural components, as well as high load components such as aircraft bearings, pump parts among others. They are also used to make cutting tools such as hobs, broaches, taps, reamers, drills, milling cutters, punches, and dies. Such wide application portfolio has benefitted the overall segment growth. Molybdenum segment is expected to witness a robust growth rate over the forecast period as well. The tool steel is usually used in applications involving materials which are difficult to machine such as gear cutters, drills, end mills among others.

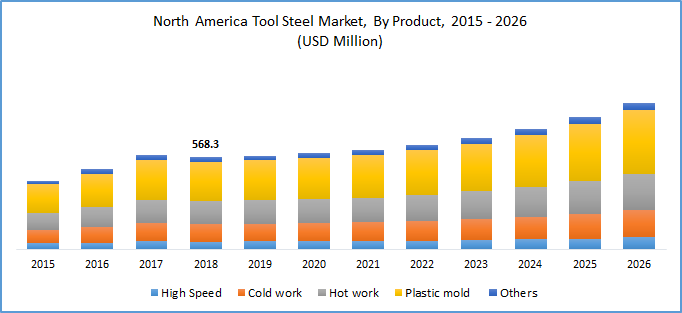

Product Outlook

By product, the market is segmented into High speed, Cold Work, Hot Work, Plastic Mold, and Others. Plastic mold witnessed the highest market penetration in 2019 and this trend is expected to continue till the end of the forecast period. Tool steels, due to the customized manufacturing processes and techniques offered by key industry participants, can match the wide diversity of plastic products and their varying requirements of manufacturing. The rising demand for plastic products is thus contributing positively to the overall segment growth.

Hot work segment is expected to grow at a estimated CAGR of 6.1% over the forecast period. Hot work type is used in applications such as extrusion, drop forging, and pressure die casting, and glass manufacturing among others. These are preferred in high pressure applications because they can sustain fluctuating temperatures as well as constantly changing thermic loads. They are instrumental in the hot forming of iron and non-ferrous jobs.

Process Outlook

On the basis of process, the market has been segmented into Rolled, Forged and Others. Rolled segment is expected to grow at a estimated CAGR of 6.0% over the forecast period. Companies manufacturing roll type have developed products that can be provided in a single roll without compromising the overall strength, have improved surface finish, and offer greater resistance to fatigue as well as mechanical damage. Such development of superior products is benefitting the overall segment growth.

Forged tool segment is expected to witness the highest growth rate from 2020 to 2026. They provide advantages such as high hardness, high resistance to fatigue and better abrasion resistance, thus making them suitable for machining a wide range of different metals. They also have the ability to maintain their sharpness of cutting edges even at high temperatures. Other desirable properties in these steels include creep resistance, corrosion resistance, as well as maintenance of strength at high temperatures. Such factors are benefitting the segment market growth.

Application Outlook

Increasing expansion of the automotive industry across the globe will drive the tool steel market. Automotive industry is highly dynamic with daily new innovations being introduced in the market. The customized requirement of the automotive applications in formation of tool and dies used for forming and working for plastic components is increasing day by day.

The automotive industry requires service with enhance reliability, superior strength and durability. Tool steel is capable of achieving these kinds of properties and maintaining the desired precision of the product. This high precision and durability of the product will drive the product demand.

Ship building requires efficient, reliable and robust tool steel to ensure the desired performance of the product suitable for the heavy-duty work. The ship parts are extremely heavy and large as compared to other counter application mentioned in the scope. The steel used for preparing the tool for this particular application must sustain the heavy stress applied on it during the overall operation.

Regional Outlook

Asia Pacific emerged as the largest market in 2019 and this trend is expected to continue its dominance till the end of the forecast period. Rising investments across India, China and Japan will proliferate the growth of Asia Pacific market size during the forecast period. Additionally, rising demand for residential as well as commercial buildings across these countries will lead to enhanced growth rate in the study period.

The material is the primary choice of automobile manufacturers in North America owing to its features of safety, strength, and durability. In addition, it is the most versatile and affordable material which has the ability to be engineered in several ways to meet the increasing performance needs of vehicles. Increasing demand for sophisticated products in the U.S. is posed to propel the market growth.

Competitive Landscape

Companies are also optimizing their overall manufacturing process to provide with products within a narrow range of compositions. They ensure that the clients receive products that have repeatable optimum performance in extreme manufacturing conditions. Companies have developed production lines that ensure critical balance of constituent materials, homogenous and fine grain size, and a superior finish. Manufacturers are trying to optimize their overall manufacturing process to provide a quality product that has better dimensional stability, better machinability, and high toughness as compared to conventional counterparts.

Companies such as Voestalpine AG, Samuel, Son & Co., Eramet SA, QiLu Special Steel Co., Ltd, Hitachi Metals, Ltd., Baosteel Group, Hudson Tool Steel Corporation, Buderus Edelstahl GmbH, Schmiedewerke Gröditz, and Tiangong International Co., Ltd. are some of the key players operating in the Tool Steel market.

License and Pricing

Purchase Report Sections

- Regional analysis

- Segmentation analysis

- Industry outlook

- Competitive landscape

Connect with experts

Suggested Report

- Global Hearing Aids Market Research Report, Size, Share & Forecast by 2017 - 2025

- Electric Ship Market Share, Size, Trends, Industry Analysis Report, 2021 - 2028

- Drug Testing Market Share, Size, Trends, Industry Analysis Report, 2021 - 2028

- Monoclonal Antibodies Market Share, Size, Trends, Industry Analysis Report, 2022 - 2030

- Natural Food Colors Market Share, Size, Trends, Industry Analysis Report, 2022 - 2030