Prepreg Market Share, Size, Trends, Industry Analysis Report, By Manufacturing Process (Solvent Dip, Hot-Melt); By End-Use (Automotive, Aerospace, Electronics, Wind Energy, Others); By Resin; By Region; Segment Forecast, 2021 - 2028

- Published Date:Oct-2021

- Pages: 101

- Format: PDF

- Report ID: PM2129

- Base Year: 2020

- Historical Data: 2016 - 2019

Report Summary

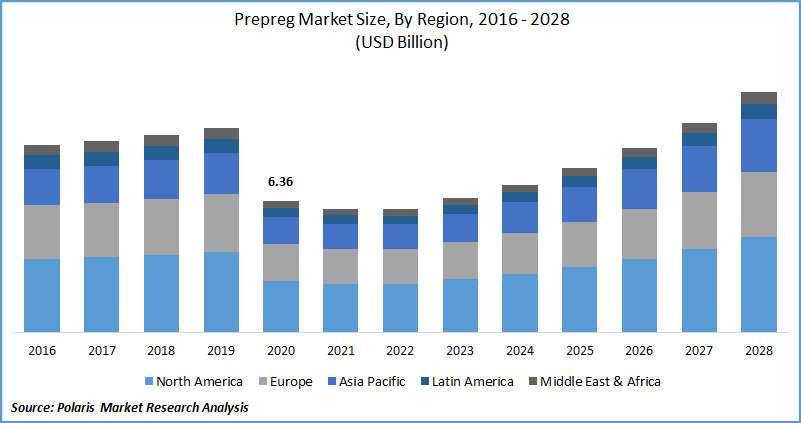

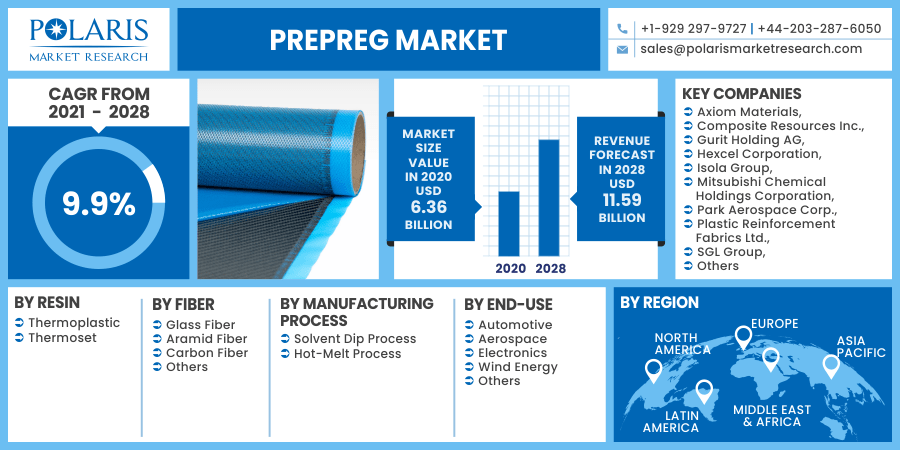

The global prepreg market size was valued at USD 6.36 billion in 2020 and is expected to grow at a CAGR of 9.9% during the forecast period. Prepreg is a reinforcement fiber, which has been pre-impregnated with a thermoplastic or thermoset resin in a specific ratio. Prepreg is a composite material that is increasingly being used in diverse applications owing to its properties such as high strength, uniformity and repeatability, reduced wastage, and less curing time.

Know more about this report: request for sample pages

Know more about this report: request for sample pages

Prepreg also offers high fatigue resistance, superior quality, a very low thermal expansion coefficient, high specific modulus and strength, and good environmental and corrosion resistance. It is used in various aircraft interiors, aerospace components, automotive parts and components, electronic-transmission applications, sporting goods, and high impact surfaces, among others.

Increasing application in the manufacturing of wind turbines coupled with the growing adoption of renewable energy sources supports the growth of the market. Growth in industrialization and urbanization has resulted in a greater sale of vehicles, increasing the demand from the automotive sector. The adoption has also gained momentum from the aerospace and defense sector.

The rising production of commercial aircrafts and increasing defense spending have accelerated the market growth. The economic growth in countries such as China, Japan, and India have encouraged global players to expand into emerging countries to tap market potential. Technological advancements and rising investments in R&D are factors expected to offer growth opportunities.

The COVID-19 outbreak has negatively impacted the prepreg market owing to operational challenges, transportation delays, travel restrictions. Factors such as disruption of the supply chain, reduced demand, and workforce impairment during the pandemic have severely affected automotive, manufacturing, aerospace & defense, wind energy industries.

Know more about this report: request for sample pages

Industry Dynamics

Growth Drivers

Prepreg is used for manufacturing in the automotive industry to substitute metals in interior and exterior applications. The growing need to reduce weight in automobiles for increased performance and safety has accelerated the adoption of prepreg. There has been increasing demand for modernized vehicles and the growing development of autonomous vehicles across the globe.

The increase in demand for passenger vehicles and the growing electrification of vehicles has increased prepreg applications in the automotive sector. Manufacturing activities have also been halted due to various government regulations across the globe. Restrictions on imports of goods to curb the spread of the virus have further contributed to hampering the market growth.

The market is primarily segmented on the basis of resin, fiber, manufacturing process, end-use, and region.

Report Segmentation

|

By Resin |

By Fiber |

By Manufacturing Process |

By End-Use |

By Region |

|

|

|

|

|

Know more about this report: request for sample pages

Insight by Resin

The resin segment has been divided into thermoplastic prepreg, and thermoset prepreg. The thermoset resins accounted for a major market share in 2020. These resin matrices include epoxy, BMI, and phenolic resins. These resins enable easy impregnation of reinforcing fibers due to their liquid state. The resin then undergoes partial curing and alters its state from liquid to solid in the B-stage. This resin is then treated at an elevated temperature to reach its final fully cross-linked form.

Insight by Fiber

The Fiber segment has been divided into glass fiber prepreg, aramid fiber prepreg, carbon fiber prepreg, and others. Carbon fiber accounted for a major market share in 2020. Carbon fiber prepreg offers high strength, flexibility, greater performance under high temperatures, and high chemical resistance. The increasing use of carbon fiber in automotive and aerospace components has boosted the market growth of this segment.

Insight by Manufacturing Process

The manufacturing process segment has been divided into solvent dip process and hot-melt process. The holt-melt process accounted for a major market share in 2020. Hot melt prepreg production is a two-stage process that includes pre-lamination of a substrate paper and impregnating the fibers. This process offers benefits such as higher product quality, reduced cost, and ease of handling.

Insight by End-Use

On the basis of the end-use, the market is segmented into automotive, aerospace, electronics, wind energy, and others. The defense segment and aerospace dominated the global prepreg market in 2020. Prepreg is increasingly being used in this sector owing to a greater need for high-performing, light-weight, and efficient parts.

Prepregs are used to replace metal parts owing to superior strength-to-weight ratio. Governments across the globe are investing significantly towards the development of military forces, boosting the adoption of prepregs in the sector.

Geographic Overview

Asia Pacific dominated the global prepreg market in 2020. The industrial growth in countries such as China, India, and Japan, rising automotive penetration, and increasing demand from aerospace and defense sectors drives this region's growth. Increasing urbanization, growing research and development activities, expansion of international players in this region, and technological advancements are attributed to the market growth.

Rising application of prepregs in electronics, construction, and manufacturing applications has been observed. Increasing awareness regarding the adoption of renewable energy sources and growing use in the wind energy sector in developing countries of this region are expected to offer market growth opportunities during the forecast period.

Competitive Landscape

The leading players in the market include Axiom Materials, Composite Resources Inc., Gurit Holding AG, Hexcel Corporation, Isola Group, Mitsubishi Chemical Holdings Corporation, Park Aerospace Corp., Plastic Reinforcement Fabrics Ltd., Renegade Materials Corporation, SGL Group, Solvay Group, Sunrez Corporation, Teijin Limited, Toray Industries, Inc., and Ventec International Group.

These players are expanding their presence across various geographies and entering new markets in developing regions to expand their customer base and strengthen presence in the market. The companies are also introducing new innovative products in the market to cater to the growing consumer demands.

Prepreg Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2020 |

USD 6.36 billion |

|

Revenue forecast in 2028 |

USD 11.59 billion |

|

CAGR |

9.9% from 2021 - 2028 |

|

Base year |

2020 |

|

Historical data |

2016 - 2019 |

|

Forecast period |

2021 - 2028 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2021 to 2028 |

|

Segments covered |

By Resin, By Fiber, By Manufacturing Process, By End-Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Key Companies |

Axiom Materials, Composite Resources Inc., Gurit Holding AG, Hexcel Corporation, Isola Group, Mitsubishi Chemical Holdings Corporation, Park Aerospace Corp., Plastic Reinforcement Fabrics Ltd., Renegade Materials Corporation, SGL Group, Solvay Group, Sunrez Corporation, Teijin Limited, Toray Industries, Inc., and Ventec International Group |

License and Pricing

Purchase Report Sections

- Regional analysis

- Segmentation analysis

- Industry outlook

- Competitive landscape

Connect with experts

Suggested Report

- Podcasting Market Share, Size, Trends, Industry Analysis Report, 2022 - 2030

- Ammunition Market Share, Size, Trends, Industry Analysis Report, 2021 - 2028

- Epilepsy Drugs Market Share, Size, Trends, Industry Analysis Report, 2022 - 2030

- Digital Signature Market Share, Size, Trends, Industry Analysis Report, 2020-2026

- Amines Market Share, Size, Trends, & Industry Analysis Report: Segment Forecast, 2018 – 2026