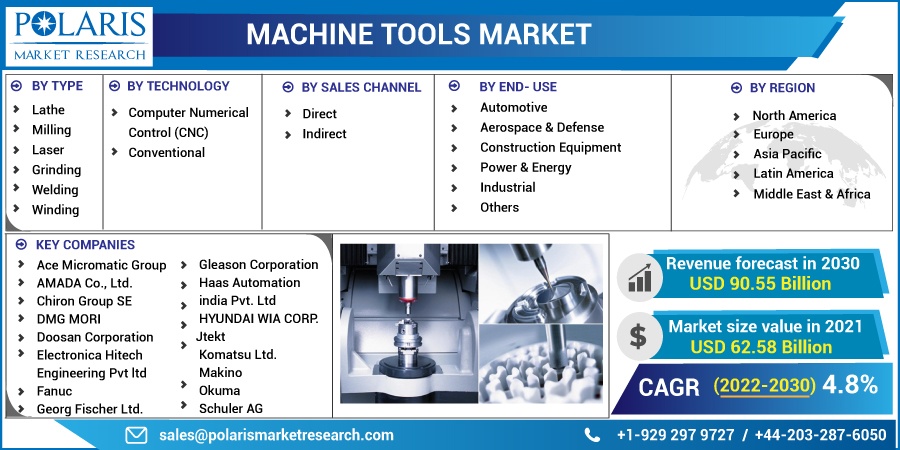

Machine Tools Market Share, Size, Trends, Industry Analysis Report, By Type (Lathe, Milling, Laser, Grinding, Welding, Winding, Others) By Technology (Computer Numerical Control (CNC), Conventional); By Sales Channel; By End-Use; By Region; Segment Forecast, 2022 - 2030

- Published Date:Jun-2022

- Pages: 101

- Format: PDF

- Report ID: PM2011

- Base Year: 2021

- Historical Data: 2018 - 2020

Report Summary

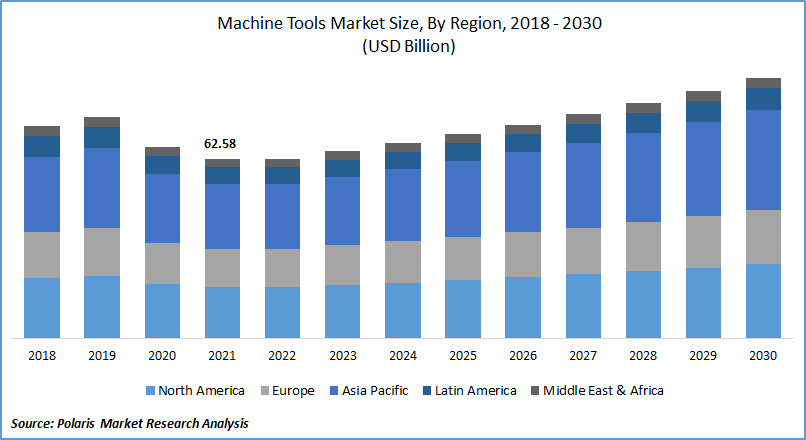

The global machine tools market was valued at USD 62.58 billion in 2021 and is expected to grow at a CAGR of 4.8% during the forecast period. The growing market demand for mass production in various manufacturing industries and favorable government regulations and policies for promoting the manufacturing sector are the key forces that stimulate the market demand for the global machine tools market. Moreover, the rising adoption of automatic tools by various manufacturing industries is another term that enhances the market's growth in the forthcoming period.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Machine tools play a crucial role in manufacturing by increasing machine utility, reducing manufacturing cycle time, being automatic or semi-automatic, and producing parts repetitively without operator assistance. Since favorable government norms regarding the promotion of the manufacturing sector across the globe is the factor escalating the global machine tools market demand.

According to the India Brand Equity Foundation (IBEF), in 2014, the Government of India initiated 'Make in India,' aiming to increase the manufacturing sector's share of the country's GDP to 25% by 2025. Also, these tools comprise various advantages, out of which mass and hassle-free production is the major one. Thus, such advent benefits of machine tools and growing favorable government initiatives for the growth of the manufacturing sector are expected to boost the machine tools market growth over the forecast years.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Industry Dynamics

Growth Drivers

The use of autonomous tools is projected to be driven by the growing number of smart factories and increased investment by manufacturers in new gears to maintain product quality and precise measurements. According to Capgemini Digital Transformation Institute, around 43% of the world has operational smart factories. While 33% have plans ready to incorporate, the remaining 8% will likely go for smart solutions in the next few years. In metal and woodworking, an automatic tool with an automatically controlled cutting process also maintains machine programs through a cam.

Industrial automation comprises various advanced technologies such as Industrial 4.0, robotics, industrial internet of thing (IIOT), artificial intelligence, etc., which are essential in improving quality, accuracy, and precision in manufacturing industries. Every stage of the manufacturing process, such as technologies, generates gigabytes of valuable data. The machine tools work in real-time to provide control of various sections involved in the manufacturing process. The growing role of these tools and rapid growth in industrial automation propel machine tools market growth over the forecast years.

Report Segmentation

The market is primarily segmented based on product type, technology, sales channel, end-use and region.

|

By Type |

By Technology |

By Sales Channel |

By End-Use |

By Region |

|

|

|

|

|

Know more about this report: Request for sample pages

Insight by Type

Lathe machine segment is projected to dominate the global market over the forecast period due to the rising adoption of lathe machines for fillet making, chamfering, slot cutting, turning, and many more. The growing technological advancements and rising adoption of automation tools will further drive market growth.

The laser machine market segment is projected to grow with the fastest CAGR in the global machine tools market due to its higher precision and finer cuts on the surface of the workpieces. Also, laser machine plays a significant role in customizing products in various manufacturing applications.

Insight by End-Use

Based on the end-user segment, the automotive segment is expected to witness the highest market share during the forecast period. Machine tools are widely used to fabricate gearbox cases, engine blocks, engine cylinder heads, transmissions, transmission housings, aluminum drive housings, flywheels, piston rods, wheels, water pumps, and other equipment. In contrast, the power and energy segment is estimated to witness the fastest CAGR in the global market growth during the forecast period due to the rise in market demand for tools in the parts used in windmills, such as rotors, bearings, blades, and gearbox housings.

Geographic Overview

Asia Pacific is projected to hold the highest revenue share in the global market since emerging countries like China, India, and others have become a hub for the manufacturing sector. This region is one of the largest exporters of goods & services considering the global scenario. The population is also enormous in the region, and the number is increasing at a steady rate.

The manufacturing sector must maintain the growing requirement for products and services to support this. Hence, smart technology is increasingly incorporated into manufacturing operations since it helps companies increase their productivity, maximize their resources, and help to innovate products. Intelligent technology integration in the rural industry moved toward more sophisticated manufacturing. This transformation will allow rural industries to manufacture goods & render services digitally, which is expected to create a faster adoption in the Asia Pacific region.

Competitive Landscape

The machine tools market players include Ace Micromatic Group, AMADA Co., Ltd., Chiron Group SE, DMG MORI, Doosan Corporation, Electronica Hitech Engineering Pvt ltd, Fanuc, Georg Fischer Ltd., Gleason Corporation, Haas Automation India Pvt. Ltd, HYUNDAI WIA CORP., Jtekt, Komatsu Ltd., Makino, Okuma, Schuler AG, Spinner Machines Tools.

Machine Tools Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2021 |

USD 62.58 Billion |

|

Revenue forecast in 2030 |

USD 90.55 Billion |

|

CAGR |

4.8% from 2022 - 2030 |

|

Base year |

2021 |

|

Historical data |

2018 - 2020 |

|

Forecast period |

2022 - 2030 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2022 to 2030 |

|

Segments covered |

By Type, By Technology , By Sales channel, By End-Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Key Companies |

Ace Micromatic Group, AMADA Co., Ltd., Chiron Group SE, DMG MORI, Doosan Corporation, Electronica Hitech Engineering Pvt ltd, Fanuc, Georg Fischer Ltd., Gleason Corporation, Haas Automation Iindia Pvt. Ltd, HYUNDAI WIA CORP., Jtekt, Komatsu Ltd., Makino, Okuma, Schuler AG, Spinner Machines Tools |

License and Pricing

Purchase Report Sections

- Regional analysis

- Segmentation analysis

- Industry outlook

- Competitive landscape

Connect with experts

Suggested Report

- High Temperature Insulation Market Share, Size, Trends, Industry Analysis Report, 2022 - 2030

- Cardiac Rhythm Management (CRM) Devices Market Research Report, Size, Share & Forecast by 2019 - 2026

- Data Center Liquid Cooling Market Share, Size, Trends, Industry Analysis Report, 2022 - 2030

- Enzymes Market Share, Size, Trends, Industry Analysis Report, 2022 - 2030

- Liquid Biopsy Market Research Report, Size, Share & Forecast by 2019 - 2026