3D Printing Construction Market Share, Size, Trends, Industry Analysis Report, By Construction Type (Modular, Full Building); By Process (Extrusion, Powder Bonding, Others); By Material (Concrete, Plastic, Metal, Hybrid, Others); By End-Use; By Region; Segment Forecast, 2022 - 2029

- Published Date:Dec-2021

- Pages: 101

- Format: PDF

- Report ID: PM1666

- Base Year: 2021

- Historical Data: 2017 - 2020

Report Summary

The global 3D Printing Construction market size was valued at USD 10,590.8 thousand in 2021 and is expected to grow at a CAGR of 88.4 % during the forecast period. Compared to the traditional building method, 3D printing construction saves time and effort and leads to faster infrastructure development, waste reduction, and fewer injuries. As a result, the industry for 3D printing is expected to propel during the forecasted period. 3D printing construction is a layer-by-layer automated technique that creates complicated shape geometries from a 3-dimension model using a series of cross-sectional slices. 3D printing in the infrastructure industry reduces production time as machines used for this technology are fast. Additionally, 3-dimension printers are fully automated, which eliminates human error.

Know more about this report: request for sample pages

Furthermore, unlike traditional methods, 3D printers do not require additional tooling such as new materials, extra support, or other factors because their structures are pre-programmed. Therefore, the demand for the industry is projected to grow. COVID-19 outbreak impacted the market negatively due to the nationwide lockdown and disruption in the supply chain. The movement of goods was restricted due to which raw materials required to construct 3D printers were affected. However, the higher cost of 3D printing equipment, lack of skilled labor, and regulations imposed on 3-dimension printing can restrain the industry growth.

Know more about this report: request for sample pages

Know more about this report: request for sample pages

Industry Dynamics

Growth Drivers

The rise in the adoption of Building Information Modeling (BIM) is one of the major factors fueling industry growth. BIM is the foundation of digital transformation in the architecture, engineering, and infrastructure industry. It is a highly collaborative approach that allows architects, real estate developers, engineers, manufacturers, contractors, and other infrastructure professionals to plan, design, and create a structure or building in a single 3D manner.

The market is booming due to reduced production costs on materials waste. 3D printers use the exact amount of materials needed, allowing cost reduction. Additionally, 3-dimension printers can use recycled materials that benefit the environment. These factors contribute to cost reduction, therefore, propelling the market growth. Factors such as reduction in injuries of construction workers in the fields, reduced material consumption, improved safety, less reliance on human resources, better branding and market share, durable and sustainable infrastructure are encouraging companies to adopt this technology.

Report Segmentation

The market is primarily segmented on the basis of construction type, process, material, end-use, and region.

|

By Construction Type |

By Process |

By Material |

By End-use |

By Region |

|

|

|

|

|

Know more about this report: request for sample pages

Insight by Construction Type

On the basis of construction type, the market is segmented into modular, and full building infrastructure. The modular segment is expected to grow at a considerable rate during the forecast period due to its benefits such as saving time and labor cost. This technology allows manufacturers to print 3D construction pieces on-site, lowering inventory and warehousing space needs. Modular construction is used to print objects, spare parts, and equipment as needed, providing consumers with a higher level of personalization.

Insight By Process

On the basis of the process, the market is segmented into extrusion, powder bonding, others. The extrusion segment is expected to dominate the market by holding the highest market share in the industry. In the field of digital construction, extrusion 3-dimension printing is currently the most widely used process. The material is pumped, extruded, and deposited in this automated infrastructure process.

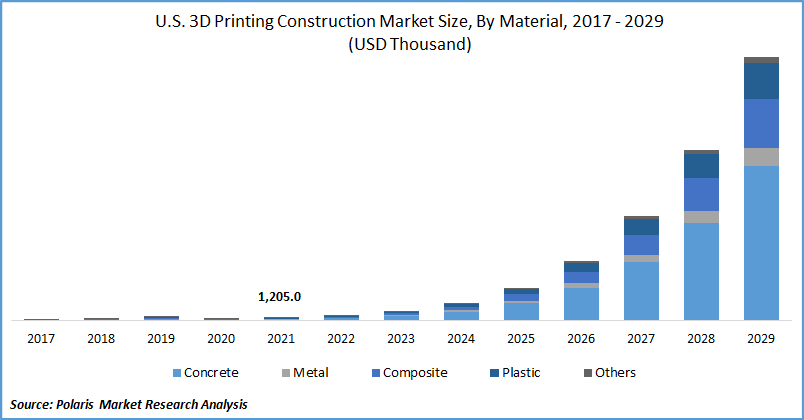

Insight By Material

On the basis of material, the market is segmented into concrete, plastic, metal, hybrid, and others. The concrete segment is expected to dominate the market over the forecast period. Concrete 3D printing is gaining popularity among architects and construction companies. Concrete 3-dimension printing is faster, cheaper, safer, and more efficient than traditional manufacturing. Furthermore, with the use of a concrete 3D printer, construction can be performed to a higher degree of resiliency and geometric complexity.

Insight By End-Use

On the basis of end-use, the market is segmented into building and infrastructure. The building segment is expected to account for the largest share in the market. The building segment is further divided into residential, commercial, and industrial. The building segment is driven by the rising level of urbanization in developing countries, coupled with an increasing number of government initiatives for infrastructure.

Geographic Overview

Asia-Pacific region dominated the market for 3D printing construction. The majority of countries in the region are spending on infrastructure for the growth of their economies. With the increasing level of urbanization and technological advancement market for 3D printing, the infrastructure industry is growing in the region. The Ministry of Electronics and Information (MeitY) of the Government of India is developing a 3-dimension printing policy aimed at encouraging industrial 3-dimension printing and promoting domestic enterprises in overcoming technical and economic challenges. In Japan, 3-dimension printing in construction is growing, driven by the demand for more efficient, cost-effective processes and higher-performance materials overall.

Competitive Insight

The leading players in the market include AI build, Apis Cor, Branch Technology, Cazza Construction Company, Centro Sviluppo Progetti, Cybe Construction, Icon, Imprimere Ag, Monolite UK., Mx3D, Sika, Skanska, WinSun, XtreeE, Zhuoda Group. These companies are adopting several expansion and collaboration strategies to strengthen their market presence.

For instance, in 2020, Skanska has collaborated with Loughborough University in the United Kingdom to advance the use of 3D printing technology in the infrastructure industry. US-based Pikus Concrete has partnered with Sika to commercialize 3D concrete printing technology in the construction business and fulfill its vast potential. In 2020, QOROX, CyBe partner on 3D printed park benches for New Zealand city. The companies are collaborating with Hamilton City Council to build 3D concrete printed park benches, which will be the country's first application of this technology.

3D Printing Construction Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2021 |

USD 10,590.8 thousand |

|

Revenue forecast in 2029 |

USD 1,792,980.6 thousand |

|

CAGR |

88.4% from 2022 - 2029 |

|

Base year |

2021 |

|

Historical data |

2017 - 2020 |

|

Forecast period |

2022 - 2029 |

|

Quantitative units |

Revenue in USD Thousand and CAGR from 2022 to 2029 |

|

Segments covered |

By Construction Type, By Process, By Material, By End-Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Key Companies |

AI build, Apis Cor, Branch Technology, Cazza Construction Company, Centro Sviluppo Progetti, Cybe Construction, Icon, Imprimere Ag, Monolite UK., Mx3D, Sika, Skanska, WinSun, XtreeE, Zhuoda Group |

License and Pricing

Purchase Report Sections

- Regional analysis

- Segmentation analysis

- Industry outlook

- Competitive landscape

Connect with experts

Suggested Report

- Battery Management System Market Research Report, Share and Forecast, 2017 – 2026

- Telepresence Equipment Market Share, Size, Trends, Industry Analysis Report, 2021 - 2028

- Hybrid Seeds Market Share, Size, Trends, Industry Analysis Report, 2022 - 2030

- Contrast Media Market Share, Size, Trends, Industry Analysis Report, 2021 - 2028

- Automotive Finance Market Share, Size, Trends, Industry Analysis Report, 2021 - 2028